If you're still having issues with your TCM after it has been refurbished. Here are some general tips to help you further troubleshoot the issue:

- First, check that the vehicle's car battery is fully charged and getting a good connection.

- Check the fuses.

- Inspect the pins on both the harness plug as well as the TCM and make sure the pins are not pushed back on the harness plug. If some of the tabs are broken on the TCM plug the harness will have to be manually pushed in further towards the TCM to ensure a good connection.

- Clean the pins with electronic cleaner on both the harness plug as well as the TCM itself and inspect for any dirty or receding pins.

- Check the transmission fluid. If it's very dark and the filter is full of debris, it'll show trouble codes and the A/T along with the check engine light might come on. This is highly likely if the transmission fluid was never serviced and the vehicle has over 75,000 miles.

Perform a hard battery reset with the TCM plugged back into the vehicle to clear any remaining codes and reset the TCM:

- Remove the key from the ignition.

- With the battery removed, to ensure there is no power, short the battery cables in the vehicle and connect the positive and negative cables together for at least 20-30 minutes.

- Reconnect the battery cables starting with the positive cable on the battery first.

This will reboot all the computer modules including the TCM and make the vehicle relearn its own values.

It's recommended to have the vehicle idle for a few minutes then take it for a drive at least 15-20 minutes after the hard battery reset.

It might idle rough at first and shift strangely but it should smooth out after the drive.

If you're not confident in doing the hard battery reset, simply leave the car battery disconnected overnight. The main goal is to drain the voltage in the computer modules to reboot them.

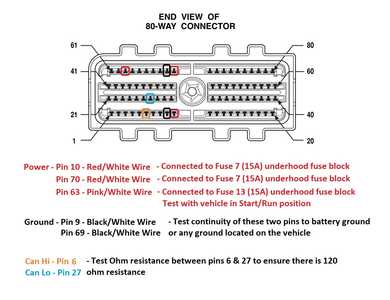

Troubleshoot 'No Communication' by using a multimeter, and check that there is continuity between the battery and the pins on the harness plugs. Testing the wiring harness pins for any connectivity issues:

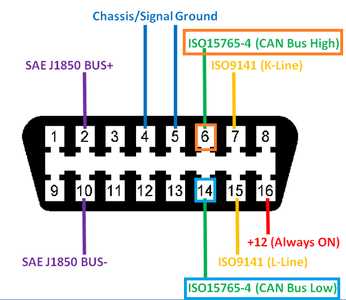

For any communication issues, with the ignition-on, make sure that you do an ohm test between pins 6 and 27 on the harness plug for any remaining U0100 and U0101 (no communication) issues that are still present after the repair. There should be 120-ohm resistance.

If there is no ohm resistance present when you test between pins 6 & 27 then the issue is not the TCM. Check the pins and wiring all the way to the OBDII connector pinout.

Check the wiring harness for any pinched or torn wiring, check & clean the connector pins on the harness plug, and inspect closely with a flashlight for any corrosion or receding pins.

Pin 6 on the TCM plug should have continuity to Pin 6 on the OBDII connector under the dash driver-side. Pin 27 on the TCM plug should have continuity to Pin 14 on the OBDII connector.

General Motors (GM) Allison TCM T14 A50 2009-2015 80-Pin Connector Pinout:

Gear shift indicator not working properly, the vehicle won't start, or the vehicle is stuck in limp mode (3rd gear) and won't move:

- Cleaning the connectors on the plug and doing a hard battery reset didn't help check the NSBU.

- The NSBU (Neutral Start Back-Up) Switch is mounted to the transmission and needs to be inspected especially the connector to make sure it's getting a good connection.

- These are notorious for failing on the 2001-2005 Allison transmission however for 2009-2015, it should still be checked if it's still in limp mode.

Getting codes for Vehicle Output Speed Sensor and stuck in 1st gear:

- Check the resistance on the speed sensor mounted to the Allison transmission.

- It should be getting roughly 2.3k-2.9k ohms at 77 degrees Fahrenheit outside for the 2009-2015 models.

- Another way to test it is by checking the voltage on the pins. Make sure the vehicle is in park position with the parking brake engaged, and slowly rev up the engine while observing the voltage increase with a multimeter.

The voltage should increase smoothly with no dropouts or glitches. The voltage amount can vary from 0.15 volts @ idle all the way up to 15 volts at higher engine revs.

Note:

General Motors (GM) has an official TSB (Technical Service Bulletin) on cleaning the TCM connector and inspecting the ground of the G102 wire terminal on the engine block for P0880 and U0101/U0100 trouble codes:

Received repaired from you. Batteries charged. Spray cleaned connections of TCM & vehicle plug. Installed. Still shifting hard into drive, (vehicle lurches forward), also stays in one gear while in Drive & won’t shift up, no response in manual shift mode). Check Engine light is on, on dash. Connected OBD code reader. Got code, PO689, (PCM/ECM power relay circuit low voltage). Cleared code. Check engine light off, on dash. Truck shifts smooth in/out of gear fine now & shifts smoothly up/down thru gears while in drive mode. Stop vehicle & shutoff key. Next restart, check engine light back on dash & same code appears in OBD code reader & shifting responds back to earlier reported shifting issues until cleared again by OBD code reader.

Any ideas or assistance with this issue would be appreciated. Didn’t have this going on before replacing with repaired TCM by your company.

Thanks much,Respectfully, Kurt Gucker

Kurt Thank you for contacting UpFix. If the truck shifted normally after clearing the codes then the TCM is working as it should. The Code P0689 is often caused by a malfunctioning PCM relay, circuit issues, and\or a blown fuse due to a low circuit. Are you getting between 13.2vand 14.4v, while the vehicle is running? checking for grounds, signal and communication through the connectors and fuse box will help isolate the issue.

Relay can wiggle loose from vibrations in the road or engine. This will cause a temporary loss of electrical flow and will typically trigger a reduction in voltage causing power warning lights along with diagnostic codes like your P0689. Taking the vehicle to an electric specialist can track down a wiring issue.